Imagine a delicate chain, each link representing a crucial component of your supply chain. A single weak link can disrupt the entire chain, leading to delays, cost overruns, and reputational damage.

Understanding the Supply Chain Landscape 🗺️

A supply chain is a complex network of interconnected businesses involved in the production and distribution of goods and services. It includes suppliers, manufacturers, distributors, retailers, and consumers.

Common Supply Chain Risks ⚠️

Several factors can disrupt supply chains, including:

- Natural Disasters: Earthquakes, floods, and hurricanes can damage infrastructure, disrupt transportation, and impact production.

- Geopolitical Risks: Trade wars, political instability, and terrorism can disrupt supply chains.

- Economic Fluctuations: Economic downturns can lead to reduced demand and increased costs.

- Supplier Performance Issues: Supplier failures, quality issues, or financial problems can impact the supply chain.

- Cybersecurity Threats: Cyberattacks can compromise sensitive data and disrupt operations.

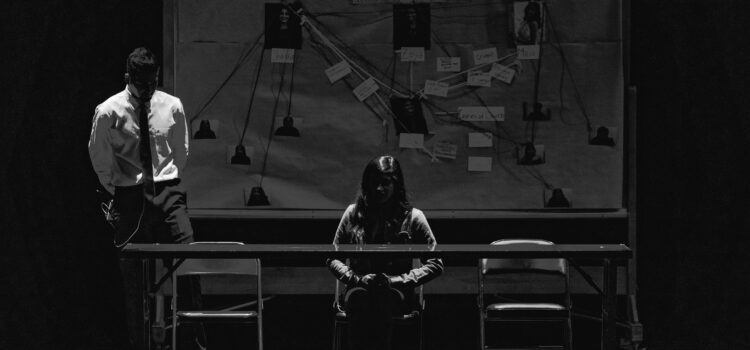

Identifying Supply Chain Risks 🔍

To effectively manage supply chain risks, you must first identify them. Here are some strategies to help you:

- Risk Assessment: Conduct a thorough risk assessment to identify potential vulnerabilities in your supply chain.

- Supplier Evaluation: Evaluate the financial stability, operational capabilities, and risk management practices of your suppliers.

- Supply Chain Mapping: Map your supply chain to visualize the flow of goods and identify potential bottlenecks.

- Scenario Planning: Develop scenarios to simulate different potential disruptions and test your response plans.

Assessing Supply Chain Risks 📊

Once you’ve identified potential risks, you need to assess their likelihood and impact. Here are some factors to consider:

- Severity: How severe would the impact be if the risk materializes?

- Likelihood: How likely is the risk to occur?

- Controllability: How much control do you have over the risk?

Mitigating Supply Chain Risks 🛡️

To mitigate supply chain risks, you can implement the following strategies:

- Diversification:

- Multiple Suppliers: Don’t put all your eggs in one basket. Diversify your supplier base.

- Multiple Production Facilities: Establish production facilities in different regions to reduce the impact of localized disruptions.

- Risk Transfer:

- Insurance: Purchase insurance to protect against potential losses.

- Outsourcing: Outsource non-core activities to reduce risk.

- Risk Mitigation:

- Inventory Management: Implement effective inventory management strategies to avoid stockouts and excess inventory.

- Quality Control: Establish robust quality control procedures to ensure product quality.

- Supply Chain Visibility: Use technology to track and monitor your supply chain in real-time.

- Emergency Preparedness:

- Develop Contingency Plans: Create contingency plans to address potential disruptions.

- Regularly Test Plans: Conduct regular drills to ensure that your plans are effective.

By understanding and addressing supply chain risks, you can build a more resilient and efficient supply chain. Remember, a proactive approach to supply chain risk management is essential for long-term success.